Just How Membrane Switches Over Contribute to the Sturdiness of Electronic Control Panels

Membrane layer switches play a critical duty in improving the toughness of digital control panels, mainly with their multi-layered building which offers reliable defense against environmental variables such as wetness and dust. The lack of moving components considerably decreases the likelihood of mechanical failures, making membrane changes perfect for demanding applications.

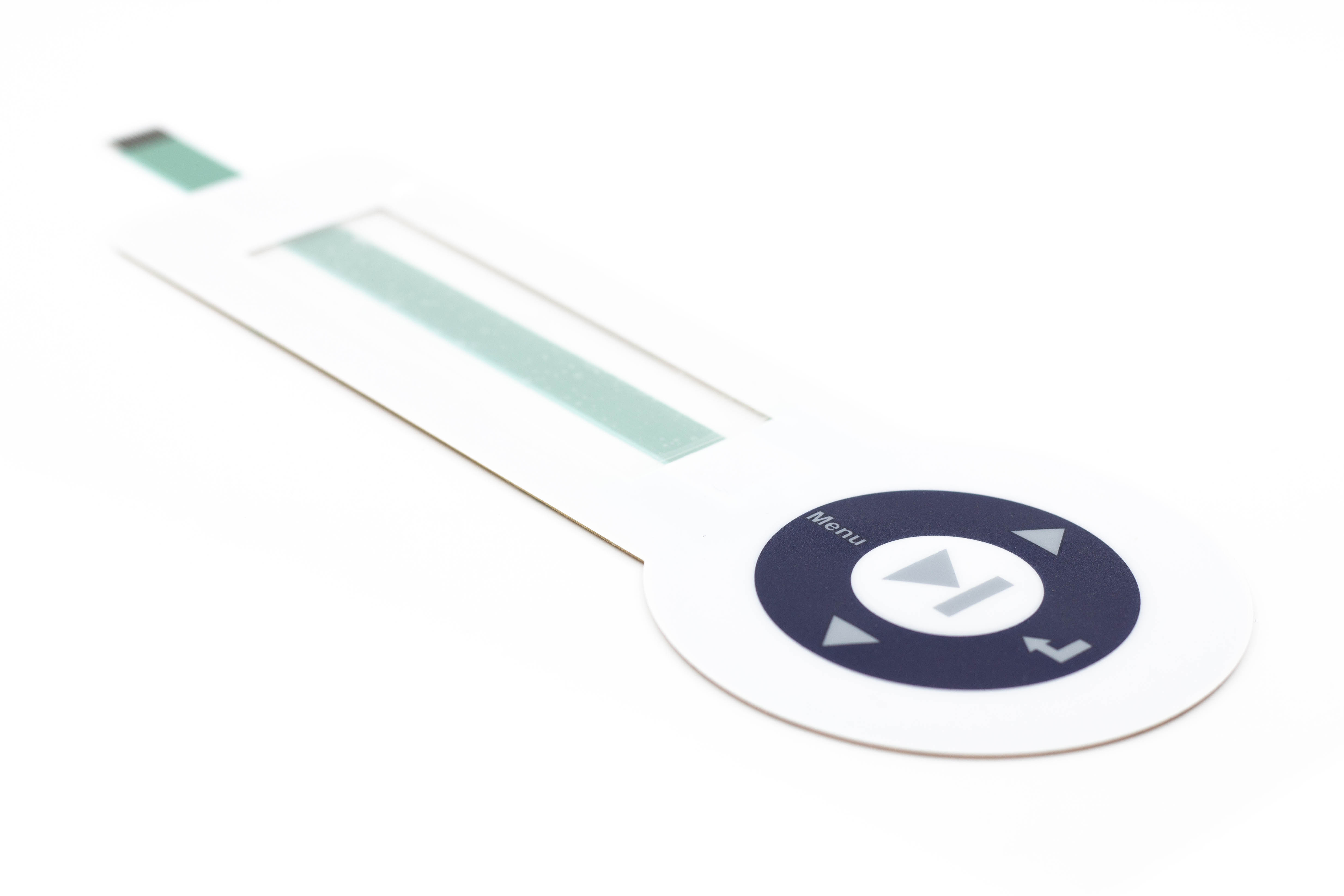

Meaning of Membrane Switches

Membrane switches are created to be slim and light-weight, making them suitable for applications where area is limited. They can be made in various shapes, sizes, and colors, offering flexibility in style that satisfies visual and useful needs. In addition, membrane switches can incorporate different innovations, such as responsive comments and LED indications, boosting user experience.

Due to their construction, membrane layer buttons are usually immune to dust, moisture, and general wear, contributing to their longevity in requiring settings. Their smooth layout not just assists in very easy cleansing but additionally minimizes the risk of mechanical failing, making them a favored choice for producers seeking reliable interface in their digital control board.

Security Against Ecological Aspects

The design of membrane switches naturally gives a level of security against various ecological aspects, which is important for maintaining capability in tough conditions - Membrane Switch. These buttons are usually created with layers of flexible products that protect internal parts from dampness, dust, and contaminants. By enveloping the circuitry, membrane layer changes minimize the danger of brief circuits and corrosion, which can dramatically hinder performance

Moreover, using durable adhesives and sealers during production improves their resistance to environmental challenges. Membrane switches can sustain exposure to chemicals and solvents, making them ideal for industries such as food processing and healthcare, where health and sanitation are extremely important. Their seamless surface style also protects against the accumulation of dust and bacteria, promoting simpler cleaning and upkeep.

Temperature level changes are another ecological issue, and membrane layer switches are engineered to operate effectively throughout a large range of temperature levels (Membrane Switch). This adaptability makes sure that control board continue Your Domain Name to be operational in numerous setups, from commercial settings to customer electronics

Influence On Customer Communication

User communication with electronic control panels is substantially affected by the layout and capability of membrane switches. These switches offer a responsive user interface that enhances the general customer experience, enabling for intuitive navigating and control. Their receptive nature guarantees that users obtain instant comments upon activation, which is critical for tasks needing precision and performance.

Furthermore, the smooth surface of membrane changes promotes simple cleaning and upkeep, advertising customer self-confidence in the reliability of the user interface. This cleanliness is specifically important in environments click here to read where health is extremely important, such as clinical or food handling setups. Additionally, the small and lightweight style of membrane changes adds to the aesthetic appeal of control panels, encouraging user involvement via a modern and streamlined look.

Furthermore, the assimilation of aesthetic components, such as printed symbols and backlighting, assists individuals rapidly identify features, lowering the finding out curve linked with brand-new devices. Consequently, individuals can operate devices more effectively, bring about raised performance and complete satisfaction. In recap, membrane layer buttons play a critical role in boosting individual interaction by combining performance, aesthetic appeals, and ease of usage, eventually leading to improved functional efficiency.

Style Flexibility and Customization

Style flexibility and personalization are vital aspects of membrane layer switches, making it possible for producers to customize electronic control board to particular applications and customer requirements. This flexibility enables for the integration of various style components, more such as shades, graphics, and structures, which can enhance the visual allure and customer involvement of the control board.

Membrane layer buttons can be tailored in size and form, accommodating a wide variety of gadgets and applications, from commercial equipment to customer electronics. This adaptability ensures that producers can produce instinctive interfaces that align with individual assumptions and functional needs. In addition, the capacity to incorporate special attributes such as backlighting or responsive feedback further boosts usability, enabling a much more interactive experience.

Additionally, the manufacturing process for membrane layer changes supports the rapid prototyping of styles, allowing makers to repeat and improve their concepts rapidly. This capability not only speeds up the advancement timeline however also ensures that the end product fulfills details practical and aesthetic requirements.

Cost-Effectiveness and Durability

Cost-effectiveness and durability are considerable advantages of membrane buttons, making them an attractive option for makers and end-users alike. These buttons are generally more economical to create than typical mechanical buttons, mostly because of their simplified production processes and the decreased number of parts needed. This expense advantage prolongs not only to initial production however also to lasting functional costs, as membrane layer buttons usually call for much less upkeep and have a lower failure rate.

Additionally, the long life of membrane layer switches adds to their overall worth. Created from resilient materials, they are resistant to environmental aspects such as dampness, dust, and chemicals, which can cause early wear in other switch types. The lack of moving components lessens mechanical failure, enabling membrane changes to maintain functionality over prolonged durations.

This toughness is particularly helpful in applications calling for consistent efficiency under requiring problems, such as clinical tools and industrial equipment. Ultimately, the mix of cost-effectiveness and durability makes membrane layer switches over a financially feasible selection for manufacturers, offering dependable remedies that endure the examination of time while maximizing budgetary considerations.

Final Thought

In conclusion, membrane layer buttons significantly enhance the sturdiness of digital control panels with their durable construction and protective attributes - Membrane Switch. On the whole, membrane layer switches over stand for a dependable and cost-efficient option for improving the durability and functionality of digital control systems.